Stal odporna na korozję, nierdzewna kwasoodporna gatunki i charakterystyka

Stale kwasoodporne to grupa nierdzewnych stali wysokostopowych austenitycznych, które odporne są tak jak stale nierdzewne na korozję atmosferyczną oraz na korozyjne działanie między innymi zimnego rozcieńczonego i stężonego kwasu siarkowego, kwasu fosforowego, kwasu octowego, mrówkowego itp. Najpopularniejszymi wyrobami hutniczymi, produkowanymi ze stali kwasoodpornych nierdzewnych (nazywanych również stalami szlachetnymi ), są: rury nierdzewne bezszwowe walcowane na gorąco, blachy zimno i gorącowalcowane, pręty walcowane i kute

Głównymi dodatkami stopowymi w tych stalach są:

-chrom który występuje najczęściej w ilości około 18% i odpowiada za odporność na działanie kwasów utleniających

-nikiel który przy zawartości około 8-9%, sprzyja jednorodności struktury i poprawia odporność na działanie kwasu siarkowego. W stali o zawartości 17-18% chromu i 0,10-0,20 węgla, nikiel w ilości 8% pozwala uzyskać strukturę austenityczną, ( stąd popularne, międzynarodowe oznaczenie nierdzewnej stali chromowo-niklowej "18/8" lub "18/9" ).

-molibden który poprawia odporność stali na działanie kwasów redukujących

-tytan i niob wiążą węgiel do postaci węglików, które w temperaturze przesycania 1000-1100oC nie rozpuszczają się w austenicie. Najczęściej zawartość tytanu to pięciokrotna zawartość węgla a niobu dziesięciokrotna.

-węgiel - najczęściej w ilości do 0,10%, im mniejsza zawartość węgla tym lepsza jest odporność chemiczna.

Większość stali kwasoodpornych to zmodyfikowany mniej lub bardziej materiał 18/8.

Rodzaje korozji na jakie narażona jest stal odporna na korozję (w tym między innymi austenityczna kwasoodporna):

Korozja ogólna (korozja równomierna)

Korozja ogólna, jest typem korozji najczęściej spotykanym, przede wszystkim w środowiskach kwaśnych. Efektem jej działania jest stopniowe zmniejszenie się grubości i masy materiału. W przypadku kiedy czynnikiem wywołującym korozję są roztwory kwasów lub ich mieszaniny, (na przykład przy wytrawianiu stali odpornych na korozję w kwasie siarkowym, solnym, itd.), powierzchnia jest dość gładka i najczęściej błyszcząca.

W kwasach nieutleniających, powierzchnia stali pokrywa się warstwą (przede wszystkim węglików i soli alkalicznych) w kolorze czarnym, którą łatwo można usunąć przez zanurzenie skorodowanej części w kwasie azotowym. Takie ciemne warstwy prawie nigdy nie powstają w roztworach kwasów, w których składzie są również utleniacze.

Często spotykanym sposobem służącym do określenia ubytku spowodowanego korozją równomierną jest jednostka szybkości przeciętnego zużycia przekroju, wyrażająca się zmianą wymiaru poprzecznego w mm na rok ( mm/rok). Postęp korozji można również wyrażać ubytkiem masy (gramów) na jednostkę powierzchni (metr kwadratowy) i jednostkę czasu (24 godziny), ( g/m2 ∙24h).

Korozja międzykrystaliczna

Na ten rodzaj korozji narażone są przede wszystkim, przygraniczne strefy ziarn metalu, które w wyniku zmian swojego składu chemicznego, mogą być szczególnie wrażliwe na korozyjne działanie niektórych substancji i związków chemicznych. Korozja międzykrystaliczna przesuwa się w materiale wzdłuż granic ziarn, powodując zupełne zniszczenie. W przypadkach mniej drastycznych, materiał traci swoje własności mechaniczne a przy uderzeniu brak charakterystycznego metalicznego dźwięku, w lżejszych przypadkach mogą wystąpić pęknięcia przy odkształceniach metalu. Przy tego rodzaju korozji nie występuje wagowy ubytek materiału, nawet mimo bardzo zaawansowanemu stadium korozji.

Korozja wżerowa,

Korozja wżerowa, charakteryzuje się występowaniem na powierzchni metalu ubytków w postaci wżerów, w odosobnionych punktach, przy jednoczesnym postępowaniu korozji w głąb materiału. W wyniku działania tego typu korozji, stal pokrywa się ubytkami, czasami bardzo głębokimi a niejednokrotnie (jak w przypadku blachy), może dojść do przedziurawienie materiału. Mimo tego, iż ubytek w materiale może być bardzo mały, szkody wyrządzone prze korozję wżerowa mogą być znaczną. Intensywność korozji wżerowej można scharakteryzować ilością wżerów na jednostkę powierzchni oraz podanie maksymalnej ich głębokości.

Własności mechaniczne stali kwasoodpornych austenitycznych

Zwykłe niestabilizowane stale austenityczne po przesyceniu (po obróbce zapewniającej im maksymalną odporność na działanie korozji) nie posiadają dobrych wskaźników wytrzymałościowych. Umowna granica plastyczności R0,2 najczęściej mieści się w przedziale 200÷220 MPa, a granica R1,0 w przedziale 240÷260 MPa. Parametry te dla przesyconych stali stabilizowanych są o około 20 MPa lepsze. Znacznie lepsze parametry osiągają stale austenityczne utwardzone azotem, ponieważ ich umowna granica plastyczności R0,2 wynosi minimum 300 MPa, a R1,0 minimum 340 MPa. Niską granicę plastyczności przesyconych stali austenitycznych i niewielką wytrzymałość na rozciąganie (od 500 do 750 MPa), rekompensuje ich bardzo dobra ciągliwość (wydłużanie A5 wynosi od 40 do 60%), a przede wszystkim udarność zarówno przy temperaturze otoczenia (150 do 250 J/cm2), jak i przy temperaturach ujemnych (ok. 70 J/cm2 przy temperaturze minus 196°C). W niektórych szczególnych przypadkach, rezygnując z maksymalnej odporności na wpływ korozji, parametry mechaniczne stali austenitycznych można znacznie poprawić przeróbką plastyczną na zimno, wpływa to jednak niekorzystnie na własności A5 i Z. Ten sposobów poprawiania parametrów wytrzymałości ma jednak znaczne ograniczenia, choćby ze względu na zdecydowanie gorszą odporność na korozję (korozja równomierna, naprężeniowa, wżerowa) stali zgniecionych a także ich nieprzydatność do spawania.

Stal nierdzewna oraz stal kwasoodporna znana jest na całym świecie pod nazwą stal INOX (z francuskiego acier - stal, inoxydable - nieutleniający się, nierdzewny, żaroodporny, co oznacza stal nierdzewną - ang. stainless steel)

Znak gatunku wzorowany jest na stalach według starszych norm GOST, składa się z liter oznaczających pierwiastki stopowe:

H - Chrom

N - Nikiel

M - Molibden

T - Tytan

Nb - Niob

G - Mangan

Cu - Miedź

oraz cyfr które występując po literach informują o średniej zawartości danego pierwiastka w %. W przypadku kiedy gatunki różnią się między sobą tylko zawartością węgla, dla ich rozróżnienia na początku oznaczenia przed literą H podaje się cyfry 0, 00, 1, 2

Np. znak gatunku H17N13M2T oznacza stal o średniej zwartości chromu 17% i niklu 13%, molibdenu 2% oraz dodatek tytanu.

H18N10MT - stal chromowo-niklowo-molibdenowo-tytanowa

H18N10MT - stal chromowo-niklowo-molibdenowo-tytanowa

H17N13M2T - stal chromowo-niklowo-molibdenowo-tytanowa

00H17N14M2 - stal chromowo-niklowo-molibdenowa

1H18N9 - stal chromowo-niklowa

1H18N9T - stal chromowo-niklowo-tytanowa

0H18N9 - stal chromowo-niklowa

0H23N28M3TCu - stal niklowo-chromowo-molibdenowa z miedzią i dodatkiem tytanu

Stale wg norm PN - EN, EN, DIN

Numery gatunków stali odpornych na korozję nierdzewnych, austenitycznych, według PN-EN, EN i DIN

1.4301, 1.4305, 1.4306 1.4307, 1.4310, 1.4311, 1.4401, 1.4404, 1.4432, 1.4435, 1.4436, 1.4539, 1.4541, 1.4560, 1.4567, 1.4570, 1.4878, 1.4940

Stale według AISI

AISI 301, AISI 302, AISI 303Cu, AISI 304Cu, AISI 304, 304L, AISI 316, AISI 316Ti, AISI 316L, AISI 321, AISI 904L

Zobacz pozostałe stale specjalne wysokostopowe

stal do pracy przy podwyższonych temperaturach

stal kwasoodporna

stal nierdzewna

stal żaroodporna, żarowytrzymała

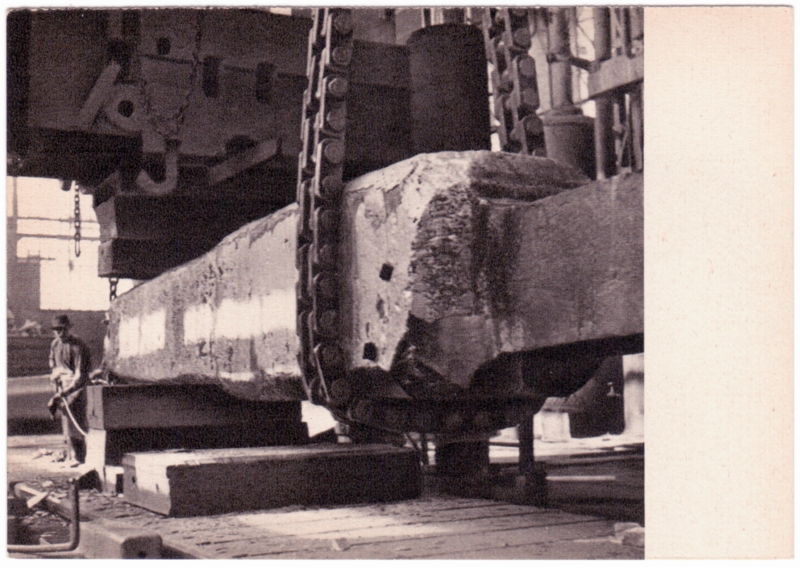

Ze stali odpornych na korozję kwasoodpornych austenitycznych - (stainless steel - INOX), firma posiada w ofercie - blachy zimnowalcowane i gorącowalcowane w wielu grubościach i różnych formatach, rury kwasoodporne bez szwu oraz ze szwem, pręty kute i walcowane, profile ( kątowniki, ceowniki, profile zamknięte), odkuwki swobodnie kute.